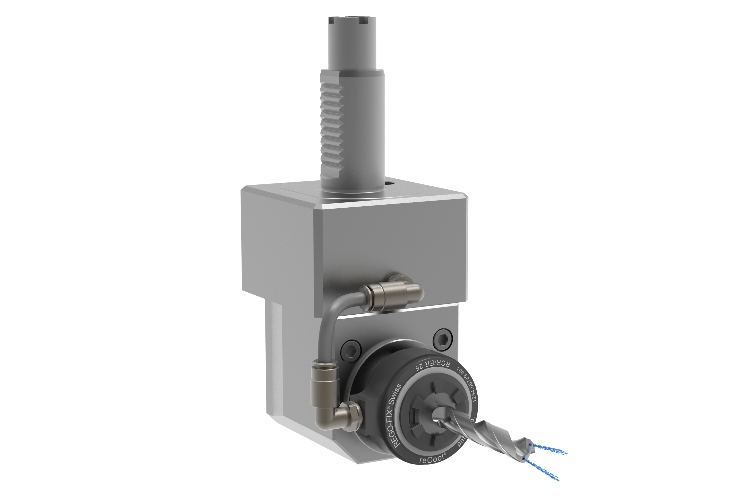

Regofix – Accessory for internal supply reCool

The rotating system for internal lubrication for reCool mandrels and motorized heads is a really revolutionary technological innovation for anyone using lathes or performing turning machining. The excellent innovation is due to the possibility to change a motorized head with no internal lubrication adding the passage of the lubricant. All this in less than 2 minutes and at very low cost. Imagining the tremendous benefits this brings is really a simple logical step.

Watch the video to see how to implement the internal lubrication on motorized heads in 2 minutes

No investment for a new motorized head, no need for maintenance of the sheaths, no waiting or downtime.

The reCool system can be used with ER collets on motorized mandrels with external metric thread (ISO 15488/DIN 6499) and supports speeds of up to 12,000 rpm and refrigerant pressure up to 58 bar / 840 PSI. As mentioned, the reCool collet does not require any maintenance thanks to self-lubricating ball bearings and can be used with internally cooled tools (with watertight DS discs) or with lubrication device (with KS discs).

The traditional supply systems of external lubrication have a poor ability to adjust the nozzles since they are rigid and with limited and predetermined diameters and lengths. These limits cause great loss of lubrication and consequently bad chip removal. The non-perfect lubrication of tools in machining therefore increases the cutting forces, reducing the life of the tools themselves, and worsens surface finish. The reCool internal lubrication system on the contrary ensures with simplicity and cost-efficiency perfect lubricant supply for all types of tool (including difficult access machining), the total absence of lubricant dispersion, an amount of lubricant optimized for each tool and unparalleled chip removal.

- CATEGORY

- TAGS

Italiano

Italiano  English

English