Rego-fix – Locking device powRgrip

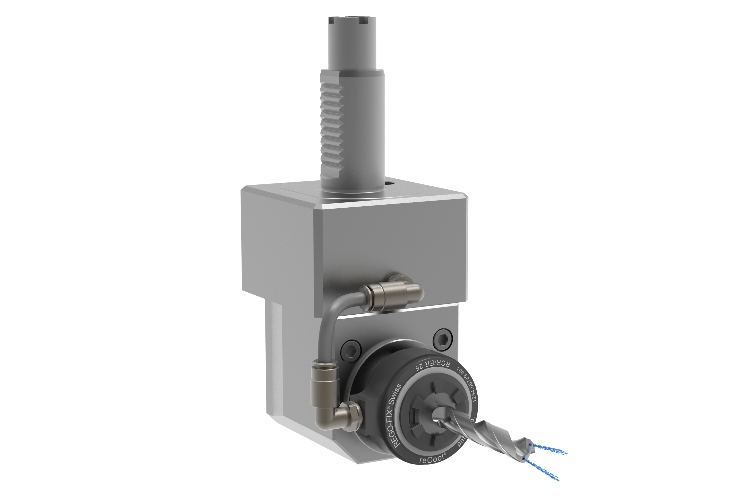

The powRgrip tightening device for cold interference is patented by Rego-fix and is a step directly in the future of precision tool locking.

The immediately visible advantages are the ease and speed of use.

Watch the video to see the powRgrip device in operation without heat development

Ideal for HSC/HPC machining, guarantees unparalleled speed in tool change without any risk for the operator. The combination of a run-out guaranteed under 3 μ and the high clamping force, make it the ideal product for the most delicate precision machining where performances and tolerances are pushed to the highest levels. powRgrip mandrels and clamps do not generate signs of wear and therefore ensure maximum durability over time and total stability and precision in tolerances and transferable power.

The one-of-a-kind powRgrip device allows performing atool change in less than 10 seconds and repeating this for well over 20,000 cycles. The only flaw is that when a mandrel needs to be replaced, you will have already forgotten about when you had bought the previous one! The absence of heat development eliminates any risk for operators and, eliminating continuous expansion, guarantees maximum product stability, continuity and reliability.

The innovative tool clamping technology developed by Rego-Fix also provides outstanding vibration reduction. This may occur thanks to the dual interference due to the couplings between the mandrel and collet and between the collet and tool. This aspect, in addition to improving precision and guaranteeing maximum stiffness, can greatly extend the life of tools, especially in cutting. All this leads the device to “repay itself” with the simple savings obtained by greater tool life and consequent lower tooling cost.

A further advantage of the device is the flexibility guaranteed by the possibility to use different types of shank. No risk of having to discard tools with a shank that is not compatible with the powRgrip device because it is possible to use cylindrical, Weldon and Whistle notch fittings or special shanks with h6 tolerance from Ø0.2 mm to Ø25.4 mm.

The mandrels are available with internal or device lubrication, also for MQL (metallic hold collets available) and, thanks to the rings, can be balanced up to 80,000 min-1.

The powRgrip commercial offer includes TC mandrels, BT mandrels, BT-OM (for use on CNC HAAS and HURCO machines) and BT+ (compatible with the Big Plus device by BIG Daishowa), HSK-A, HSK-E, HSK-F mandrels and HSK-A SSY/PG Softsynchro tapping mandrels (with collets for tapping with dragging dial, internal cooling, integrated length adjustment screws and compatibility with h9 shanks), Capto (made in Switzerland by Rego-fix on Sandvik license) , cylindrical mandrels for use also as extensions.

- CATEGORY

Italiano

Italiano  English

English