Diatool – Work with us Diatool – Multi-cutting reamers, Boring heads

Diatool has boring as the one and only “core business” and more than 35 years of experience in the design, manufacture and repair of braze-welded expandable multi-sharp reamers.

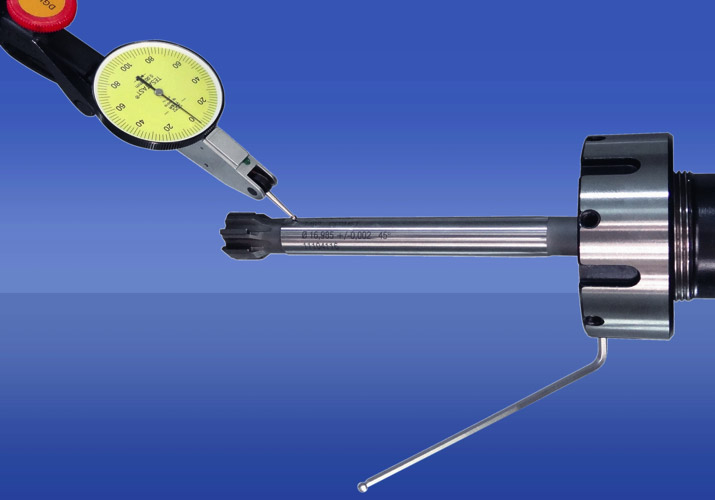

The advantage of this type of multi-blade tool is the micrometric adjustment that, with the simple rotation of an expansion screw, allows dimensionally recovering the measurement that is lost due to wear of the cutter. Thanks to the expansion tool life is therefore increased many fold. The adjustment of the reamer or, more correctly of the borer, is such a simple operation that it can be performed by any operator within seconds, but guarantees the tool to prolong its life up to 6 times compared to a fixed reamer.

Once the possibility of expanding the reamer is complete, it may be returned to Uvat that, through the same technicians and the same technology with which it was produced, will completely restore it. The tool is completely overhauled and new blades are braze welded on the same. This operation of regeneration and brazing of the reamer ensure the tool returns to its original state, with a life exactly identical to that of the new reamer, but with a much lower cost.

Diatool has long been a reliable partner of Uvat and is now known nationally for a level of quality and constant production at the highest standards of the market. Constant technological research in the field of precision boring, fast deliveries (2-3 days if necessary) and an in-depth knowledge of production requirements in the mechanical field, make it an essential choice for any mechanical workshop that aims to make quality their primary goal.

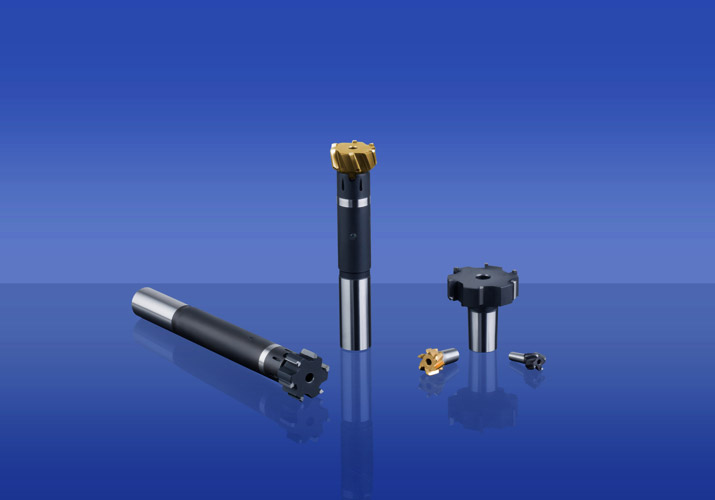

Diatool braze-welded adjustable mono-block reamers guarantee perfect hole boring, a wide range of products and finishes suitable for every application (different lengths, for blind or passing holes, continuous or interrupted cutting etc.), competitive prices for standard and specially designed products and precision in terms of unreachable run-out and circularity.

Diatool ensure dimensional accuracy with tolerances IT5, IT6, and IT7 and excellent surface roughness (Ra, Rt, Rz).

Even in unmanned machining, manufacturing consistency and precision of Diatool reamers allows avoiding any type of waste. High-speed machining in total absence of vibrations, wide choice of tool types, sizes, lengths, geometries, materials and coatings. Each reamer is manufactured at the tolerance required by the customer in a few days and is delivered ready to be mounted in the machine.

Diatool blades meet the latest technological requirements (micro-grain carbide, Cermet, CBN, PKD/PCD) to which it is possible to combine different PVD coatings (TiN, TiAlN, AlTin Nano, ATN, HCL, Helica, HCL, AlTiCr N, ATC, ZrCNT, NCA) ensuring particularly high cutting speeds.

Depending on the material and machining requested it is possible to opt for: Cermet blades for steel and cast iron, carbide coated for grey cast iron and steel, nude carbide and PCD cutters

Although expandable mono-block multi-blade reamers are the best choice in most mechanical machining, Diatool also produces adjustable and interchangeable Boring heads, also expandable and multi-sharp, and Crowns to Bore, for diameters up to 150.599 mm.

The 10 strengths of DIATOOL:

- More than 35 years of experience in the production and regeneration of multi-sharp reamers

- Very short delivery times for standard and special reamers

- Competitive prices

- Focus only on the “core business” of reamers

- Highest quality products

- Cutting-edge technology

- Technical consultancy

- Wide range of products

- Large selection of materials and coatings

- Widespread sales and service network

- CATEGORY

Italiano

Italiano  English

English